Polyimide film

- Quality control :under ISO standards and RoHS compliant.

- Hs code: 392092

- Content :Polyimide

- Width: min 10mm max 520mm

- Color:Coffee ,gold ,black or customized colour.

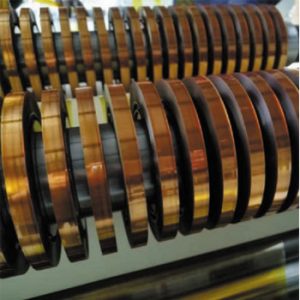

- Winding style: Pad

- Inner core size (ID):2"(52mm), 3"(76mm)

- Out Diameter: Match with 1500m-2000m per roll

- Feature: Polyimide film is a special engineering plastic film which is called "PI film"with excellent mechanical properties,dielectric properties. The Polyimide film is temperature resistance from minus 195 ℃ to 300℃. the Polyimide film is long-term and widely used in various fields

- Storage: In room temperature .Keep dry away from light direct irradiation,pollution and all kinds of mechanical outside force

Polyimide Tape is a high performance insulating tape that gets wrapping to conductor and jackets. This product provides excellent moisture and abrasion resistance, high dielectric strength and it retains much of its physical integrity after gamma radiation exposure. Polyimide Tape product operates up to 500 Degrees F (260 Degrees C).

Technical parameters

| Structure | Thickness(μm) | Weight(g/m2) | Yield(m2/kg) |

| Polyimide film 12 | 12 | 16.8 | 59.5 |

| Polyimide film 25 | 25 | 35 | 28.6 |

| Polyimide film 30 | 30 | 42 | 23.8 |

| Polyimide film 50 | 50 | 70 | 14.3 |

| Polyimide film 75 | 75 | 106.5 | 9.38 |

| Physical properties | Item | Units | Value | Test condition | |||

| Mechanical | Thickness | μm | 12 | 25 | 50 | 75 | 20℃ |

| Tensile strength | Mpa | >130 | >145 | >155 | >155 | 20℃ | |

| Elongation at break | % | 55 | 65 | 83 | 81 | 20℃ | |

| Density | G/cm3 | 1420+/-20 | 20℃ | ||||

| Electrical Parameters | Breakdown voltage | MV/m | 240 | 248 | 200 | 187 | 60Hz,20℃ |

| Dielectric constant | – | 3.2 | 3.2 | 3.2 | 3.2 | 1MHZ,20℃ | |

| Volume resistance | Ω*cm | >1010 | >1010 | >1010 | >1010 | 500V*20℃ | |

| Surface e resistance | Ω | >1013 | >1013 | >1013 | >1013 | 500V*20℃ | |

| Thermal properties | Thermal expansivity | Ppm/℃ | <35 | <35 | <35 | <35 | 100~200℃ |

| Heat shrinkage | % | <0.06 | <0.06 | <0.06 | <0.06 | 200℃*2hrs | |

Polyimide film of application

- Wire and cable insulation film

- Magnet wire insulation shielding tape

- Enamelled wire insulation auxiliary material

- Transformer and capacitor insulation film

- High temperature tape

- Motor insulation tape

Common thicknesses of polyimide film bands range from 0.025mm (1mil) to 0.13mm (5mil). Different applications require different thicknesses of polyimide film tape, so the selection of polyimide film tape needs to be based on the specific application requirements.

The tolerance range of polyimide film thickness should be determined according to the actual application scenario and product requirements. Normally, the thickness tolerance of polyimide film is about ±5%.Specifically, if the target thickness of the polyimide film is 10μm, then the tolerance range is ±0.5μm, that is, the film thickness should be between 9.5μm and 10.5μm. If the target thickness is 50μm, then the tolerance is ±2.5μm, that is, the film thickness should be between 47.5μm and 52.5μm.

It is important to note that the thickness tolerance range of polyimide films can be affected by many factors, such as coating process, substrate surface state, coating properties, and so on. Therefore, these factors need to be taken into account when controlling the tolerance range of polyimide film thickness to ensure that the film thickness is stable, uniform and meets the requirements of the product.

The elongation of the polyimide film tape is generally between 10% and 50%, depending on the thickness of the film tape, the type of material, and the manufacturing process. The elongation of polyimide film tape has a great impact on its performance in practical applications. For example, for cables with certain displacement or telescopic deformation, it needs to have a high elongation, while for some electronic components that do not need deformation, the elongation requirement is low.