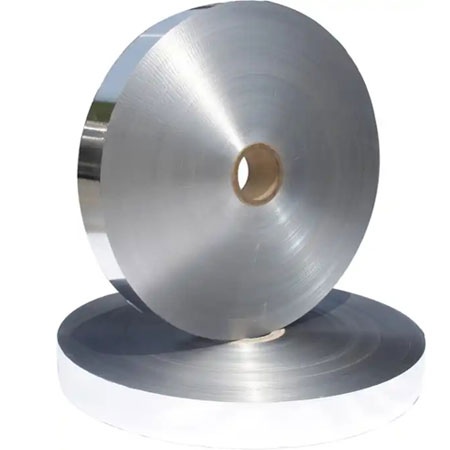

copper polyester composite tape (main CU/PET) and aluminum polyester composite tape (main AL/PET or AL/PET/AL) are two common composite tape, widely used in coaxial cable, data cable, communication cable shielding layer. Comparing the materials of these two structures, we will find that:

1. Electrical conductivity

copper polyester composite tape : Copper has very high electrical conductivity, so copper polyester composite tape is often used in applications that require high electrical conductivity, such as cable shielding and conductive connections.

aluminum polyester composite tape : Aluminum has lower electrical conductivity than copper, but is still sufficient in many applications. aluminum polyester composite tape is also commonly used for cable shielding, especially when cost considerations are more important.

2. Corrosion resistance

copper polyester composite tape: Copper may oxidize and corrode under certain environmental conditions, although anti-corrosion treatment is sometimes used. The corrosion of copper is mainly affected by ambient humidity and temperature.

ALuminum polyester tape : aluminum has good corrosion resistance, especially when the aluminum surface is formed after the alumina layer, it can effectively resist most corrosive media.

3. Mechanical strength

copper polyester composite tape : Copper has good mechanical strength and toughness, which makes copper polyester composite tape perform better in applications requiring strength and wear resistance.

aluminum polyester composite tape : the mechanical strength of aluminum is lower than that of copper, so the strength of aluminum polyester composite tape is usually not as good as that of CU/PET tape.

4: Weight

copper polyester composite tape: The density of copper is greater than that of aluminum, so the copper polyester tape is heavier than the aluminum polyester tape. In applications where lightweight needs to be considered, copper polyester tape may not be as suitable as aluminum polyester tape.

aluminum polyester tape: The low density of aluminum makes the aluminum pet polyester composite tape have obvious advantages in weight, which is suitable for application scenarios requiring lightweight materials.

5. Cost

copper polyester composite tape: The raw material cost of copper is higher, so copper polyester composite tape is usually more expensive than aluminum polyester composite tape aluminum polyester composite tape (main AL/PET or AL/PET/AL): The raw material cost of aluminum is low, making the cost of aluminum polyester tape relatively low.

6. Thermal conductivity

copper polyester composite tape: The thermal conductivity of copper is very high, and it can effectively conduct heat. This is important for applications that require thermal management.

ALuminum polyester tape The thermal conductivity of aluminum is also high, but still lower than that of copper. Therefore, for applications with high thermal conductivity requirements, copper polyester composite tape (main CU/PET) may be more suitable.