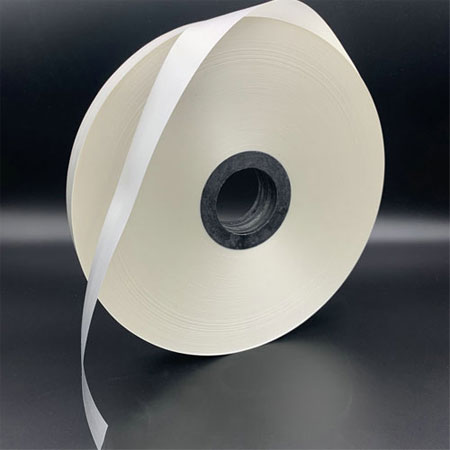

In modern industry, the protection and management of cables is crucial, especially in complex electrical systems. Polypropylene Foamed Tape (PP) is becoming an increasingly popular cable management solution due to its lightweight and durable properties.

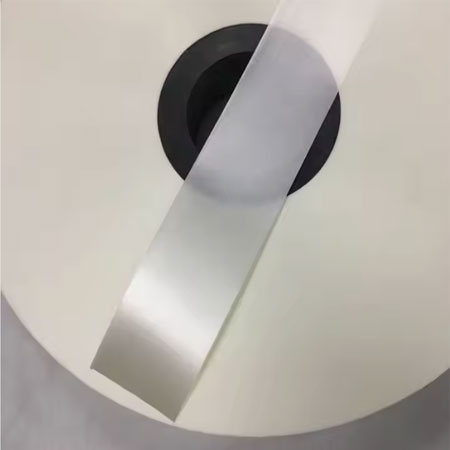

PP foam tape is polypropylene (PP) as the base material, through the foam process made of tape. The structure of this tape makes it have good elastic and cushioning properties, while maintaining the chemical resistance and aging resistance of the polypropylene material. The foaming process not only reduces the density of the tape, but also gives it excellent insulation and resistance to compression.

1. Main features

Light weight: The low density of PP foam tape reduces the overall weight in cable management. This is especially important for applications where total system weight needs to be reduced, such as aerospace and mobile devices.

Excellent insulation properties: Due to its foam structure, PP foam tape provides good electrical insulation, effectively preventing short circuits and electrical interference between cables.

Strong durability: polypropylene material has good chemical stability, can resist the erosion of various chemical substances, and has good high temperature resistance.

Good cushioning and seismic performance: The foam structure provides additional cushioning and protection, which can effectively reduce the wear and damage of the cable during use.

Easy to process and install: PP foam tape can be easily cut and pasted, adapt to different sizes and shapes of cables, easy to install.

2. Application field

Electronic and electrical industry: In electrical equipment and electronic products, PP foam tape is used to bind and insulate cables, providing effective protection and management.

Automotive industry: In the automotive manufacturing process, PP foam tape is used for cable protection, reducing vibration and friction damage to the cable, while helping the cable system finishing and layout.

Aerospace: Weight is a key factor in the aerospace sector. The lightweight nature of PP foam tape makes it ideal for managing and protecting cables.

Home appliances: In home appliances, PP foam tape is used for insulation and fixing of cables to improve product safety and durability.

3. Future outlook

With the development of science and technology, the performance of PP foam tape is also constantly improving. In the future, there may be more functional foam tapes, such as tapes with self-healing functions, further enhancing their application value in cable management. At the same time, the application of environmentally friendly materials will also become an important development direction to reduce the impact of plastic waste on the environment.